SANITARY MIXER/SCRAPE SURFACE ENGINEERED SEALS

SANITARY MIXER SEALS

ZM Technologies designs and manufactures mechanical seals for the Food, Dairy, and Pharmaceutical Industries. With over fifteen years of experience in these industries, our focus is developing mechanical seals that are designed for sanitary applications. We have innovated many designs and manufacturing processes that allow the mechanical seal to perform while remaining free and clean of product buildup, which will reduce or eliminate product contamination.

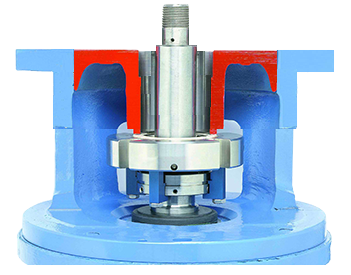

ZN MIXER SEAL

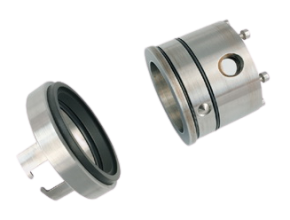

SCRAPE SURFACE HEAT EXCHANGER SEALS

With over 15 years of proven performance, the ZMT engineered Conthrem and Votator seals will outperform and outlast the OEM by 3-4 times. Seals are interchangeable. Does not require any equipment satisfactions. Your satisfaction is guaranteed

ZM Technologies manufactures OEM replacement and uniquely engineered Mechanical Seals. For over 20 years, ZMT has taken good ideas and made them better.

Our design philosophy:

- O.E.M. mechanical seals in stock, guaranteed to meet or exceed OEM specifications.

- Zero Maintenance Seals are flushless, will outperform your existing seals, and are repairable for a fraction of the price of new.

- “Keep it Simple“. Seals that have a lower cost, increased reliability, and ease of installation.

All of ZM Technologies’ engineered mechanical seals are waterless (flushless), and are repairable for a fraction of the price of new.

Our mechanical seals are easier to install than the OEM, and offer 3-4 times the life of the original seal.

Pumps – ZM Technologies’ mechanical seals will operate up to 3600 rpm and up to 300 psi. Please contact the factory with the specifics of your application for more information. All mechanical seals can be repaired by exchange kit or repair kit.

Mixers – ZM Technologies’ mechanical seals will operate up to .250″ TIR and can accomodate up to .250″ of axial growth. Please contact the factory regarding the specifics of your application for more information.

We currently manufacture and stock many mechanical seals for most sanitary centrifugal, positive displacement pumps, and scraped surface heat exchangers.

Contact the factory about the equipment in your plant for information about how ZMT engineered seals can be used in your application. ZM Technology supplies the following:

- OEM replacement Seals for Alfa-Laval Pumps.

- APV Pump OEM replacement Seals.

- Fristam® Pumps – All FP and FPX Series Pumps.

- Tri-Clover® Pumps – 114, 216, 218, 328, & 4410 C & SP Series.

- Tri-Clover® Pumps – 3EH and 4EH series pumps.

- Waukesha® Pumps – Universal 1 models 006 thru 523.

- Waukesha® Pumps – Universal 2 models 006 thru 320.

- Waukesha® Aseptic Pumps – 223, 323, 423, 523.

- Waukesha® Industrial Pumps – 5060, 5070, 5080.

- Contherm®, Cherry-Burrell, and Votater® Heat Exchangers, contact factory for details.