Specialty Products

ZM Technologies is a representative of Food Processing Equipment for the Sanitary Process Industry; these specialty dry blenders and mixers reflect our Zero Maintenance™ philosophy to reduce downtime, increase equipment life, and decrease your maintenance costs.

These products are designed, highly engineered application solutions for mixing and blending in the manufacturing processes.

Let our experienced application engineers help you build the most efficient blending and mixing solution for your application.

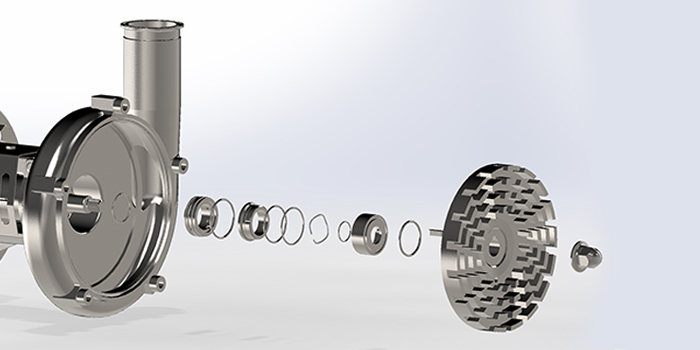

AC+ Dry Blender & Mixer

The AC+ Dry Blender uses the proven design of a tube within a tube and a centrifugal pump, but with the improved shaft and threaded impeller nut construction of the AC+ pump.

The tube within a tube design keeps dry ingredients and liquids separated until they are introduced in the mixing chamber while maximizing induction vacuum. Dry ingredients are introduced without excess air so lumping and foaming do not occur. Fast, uniform, and continuous material absorption up to 350 lbs/min.

The AC+ Dry blender can be easily integrated into current process systems.

AC+ Blenders are also suitable for liquid to liquid applications.

For more information on AC+ Dry Blenders click here.

PM Powder Mixer

Blend wet and dry ingredients together quickly and precisely with the the PM Powder Mixer. The PM Powder Mixer will save you time and money by providing optimal mixing consistency and reduced processing time. This m Mixer is set in-line to avoid limiting the batch size.

ZM Technologies can customize a powder mixer designed to specific applications in order to further maximize your operating efficiency while providing a superior end-product.

This mixer has the hopper welded to the table for perfect streamlining from table top to hopper and easy cleanup. The table top is ergonomically designed for safe and operator-friendly operation.

For more information on PM Powder Mixer click here.

ROLEC DH Dry Hop Recirculate

The ROLEC DH units utilize the SBI pump to recirculate a fermenter and simultaneously induce hop pellets dry into the stream of beer. The pellets are held in a pressurized chamber, which is purged of air using carbon dioxide (CO2). Pellets can be induced into fermenting, finished, or crashed beer. The shear pump creates a differential pressure for induction of the pellets from the hop vessel. The pellets are chopped to just the right size so they can settle during the dry hop holding period.

For more information on the ROLEC DH Dry Hop click here.

SB Series Blender

Mixing is becoming increasingly important in a wide variety of industrial processes. Today’s products are often a large mixture of ingredients; such as stabilizers, thickeners, gums, sugars and other additives. This can be challenging to provide a consistent blend quality in the most efficient manner possible.

To meet this challenge ZM Technologies offers three types of shear blenders based upon the popular competitor’s LF platform. This allows for shared wear items for your pumps and easy piping solutions.

For more information on the SB Series Blender click here.

| Model | Induce & Blend | Pump & Blend | Blend Only | Induce Only | Low Powder/ High Flow | Low Flow /High Powder |

|---|---|---|---|---|---|---|

| SBI Series | √ | √ | √ | |||

| SBH Series | √ | |||||

| DRY-blend | √ | √ | ||||

| POWDER-Max | √ | √ | √ | |||

| DRY-Hop | √ | √ | √ | √ | √ |