Sanitary PD Pumps

ZM Technologies offers Ampco Pump’s complete line of sanitary positive displacements pumps. Many value added features that are standard in our pumps that the competition charges additional for many of these upgrades. ZM Technologies offers all of these benefits and maintains 100% interchangeability, both hydraulically and dimensionally with competing pumps, like the Universal 1 and Universal 2.

Our sanitary positive displacement pumps are well-suited for a wide range of processing applications that include food processing, dairy processing, pharmaceutical, cosmetics, and more.

Our pump performance provides capacities up to 500 gpm, up to 600 psi, and viscosities up to 1,000,000 centipoise.

Processing chocolate? ZM Technologies stocks chocolate clearance rotors.

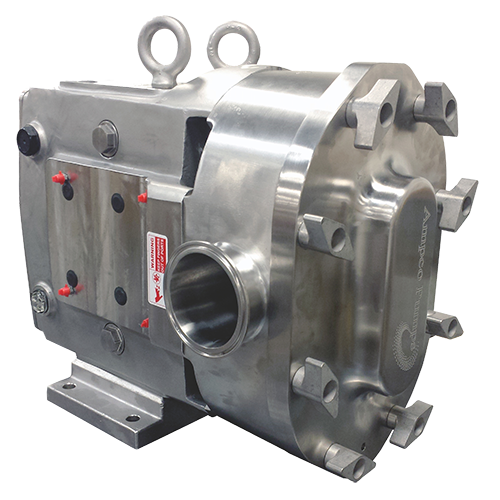

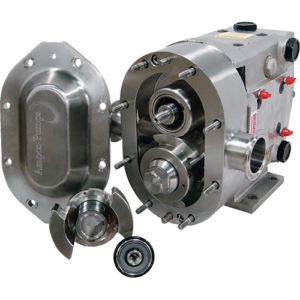

ZP Series Pumps

The ZP Series positive displacement pumps offer a 304 SS gearcase as standard, 17-4 PH shafts, and 4-way mounting. The ZP1 and ZP2 are interchangeable with the competition’s Universal 1 and Universal 2 pumps. The patented ZP3 Series offers a front-loading seal design that reduces maintenance downtime and is fully CIP-able. All of the ZP Series design advantages lead to reduced maintenance times and a faster ROI.

For more information on ZP Series (ZP1, ZP2, and ZP3) click here

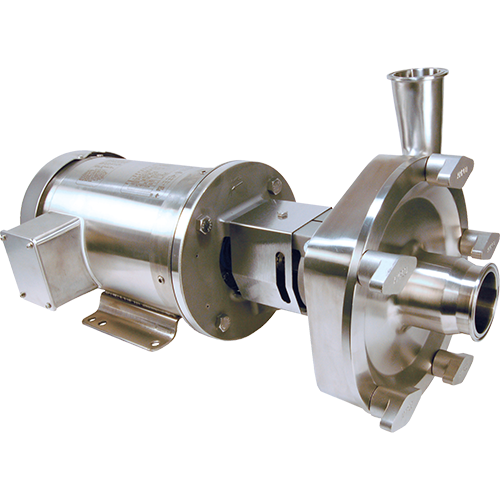

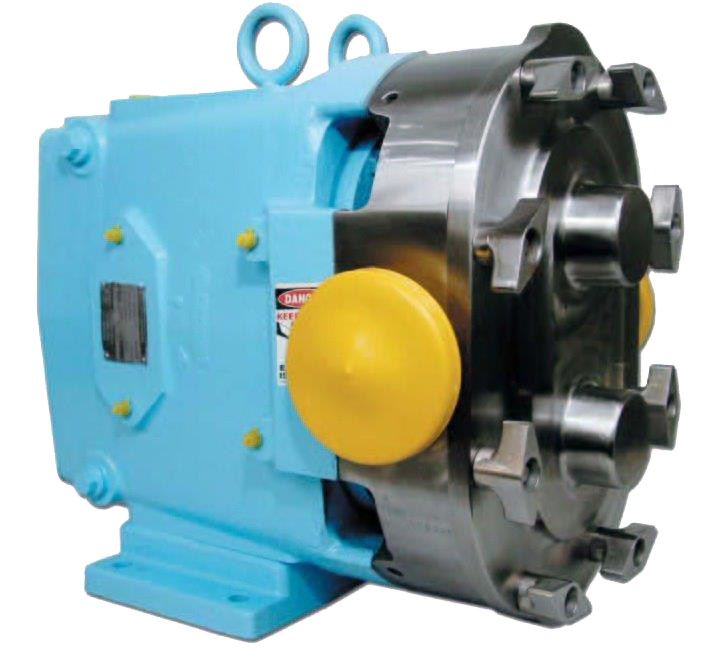

AL Series Pumps

AL Series rotary lobe pumps are an economical alternative to rotary positive displacement pumps in certain applications, like tanker unloading. AL pumps offer a standard stainless steel gear case and a front loading seal design with superior CIP-ability and ease of maintenance. All AL pumps are EHEDG certified and in conformance with 3A Sanitary Standards.

For more information on AL Series Pumps, click here

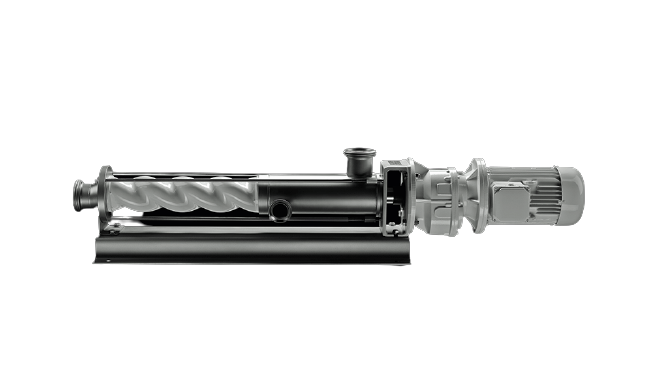

SLH Twin Screw Pumps

The SLH Series is perfectly suited for gentle, consistently metered, pulsation free product handling. Capable of handling a wide range of viscosities from 1- 1,000,000 centipoise, products with up to 60% entrained air and abrasive products. The SLH is also designed with bi-directional flow capabilities reducing product loss. The SLH is made of 316L stainless steel, and is in conformance with 3A Sanitary Standards. With running speeds as high as 3000 rpm the SLH is fully CIP-able – eliminating the need for additional CIP equipment.

For more information on SLH Twin Screw Pumps, click here

Premium Economy Pumps

Premium Economy (PE) pumps are remanufactured ZP1 / ZP2 and ZP3 pumps with new pump performance and a one year new pump warranty. PE pumps offer significant cost savings and include all standard Ampco upgrades except a stainless steel gear case. Call ZM Technology for a complete list of PE pumps currently in stock and available for immediate delivery with significant cost savings.

For more information on PE Pump, click here

Sanitary Diaphragm Pumps

ZM Technologies’ line of sanitary diaphragm pumps are manufactured by Nomad, the world’s largest & most experienced after-market AODD pump manufacturer. These pumps use 304 SS and Teflon parts and are self-priming. Air operated diaphragm pumps can handle viscous and abrasive products, can run dry without damage, and are built to last. The Nomad pumps & parts are 100% interchangeable with Wilden®.

For more information about diaphragm pump, click here

Sanitary Progressive Cavity Pumps

ZM Technologies’ line of sanitary progressive cavity pumps are manufactured by Seepex, the world’s largest & most experienced PC pump manufacturer. These pumps use 304 SS and FDA approved elastomer parts Progressive Cavity Positive Displacement pumps can handle viscous and abrasive products and are built to last. Seepex PC pump is an inexpenisve way to process viscous products that need a PD pump.

For more information about diaphragm pump, click here