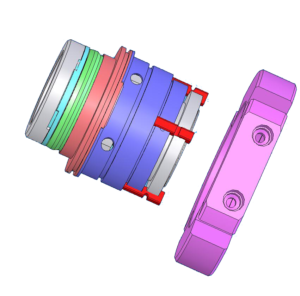

ZND DOUBLE CARTRIDGE SEAL

WHY ARE ALL DOUBLE SEALS ALIKE?

SHOULD DOUBLE SEALS ALWAYS USE A LOT OF WATER?

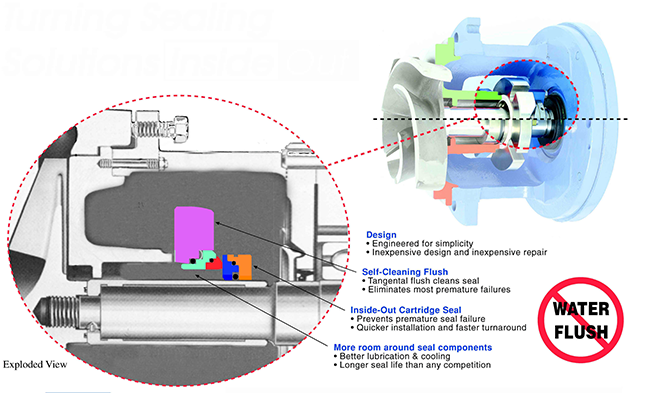

The ZMT ZND double/tandem seal is the next generation double seal. Unlike the competition, the ZND seal is designed to be universal in its use, to fit a broad range of applications, and be easily configured to any customer’s most difficult applications.

The ZND seal concept uses interchangeable inner cartridges, for ease of change in seal faces and elastomer materials. The ZND’s engineered high design limits allow it to fit many applications without any changes to the seal or equipment. This unique design allows for maximum customer flexibility in seal use and minimal inventory to solve the most difficult sealing application.

The ZMT ZND double/tandem seal is the next generation double seal, because the Inner Cartridge can be changed to do the following:

- Seal design uses an internal pumping ring. Tandem seal design generates little heat, so seal uses less water than the competition.

- Repair is simple, convenient, and inexpensive through a parts kit, or a complete inner cartridge.

- Four different Inner Cartridges to meet your needs:

- Two Double/Tandem Seals:

- ZND standard configuration for most application.

- ZDT a shortened ZND seal for applications that have minimal distance to bearing frame..

- Two Single Seals (use same gland as the double seals above):

- ZDN standard configuration for most applications.

- ZH seal for high temperature applications.

- Two Double/Tandem Seals:

ZND’s unique features are as follows:

- Bi-directional pumping ring for better cooling and for an ultra-low flush, which dramatically reduces water consumption.

- The least expensive tandem seal on the market. Even priced better than most double seals.

- Repair is inexpensive and easy with the Inner Cartridge.

- Convenient one-side flush connections.

- True tandem design offers full redundancy. Outer seal can operate under full product pressure, up to 400 psi.

The ZND seal family is designed to operate cooler at higher pressures than the competition, typical operating temperatures are up to 400 deg. F., and up to 400 psi.

Consult the factory for the specifics of your application for a recommendation.

Remember . . . . . . . Heat Kills.