SHEER BLEND – SBH/SBI SERIES BLENDER

Mixing is becoming increasingly important in a wide variety of industrial processes. Today’s products are often a large mixture of ingredients, such as stabilizers, thickeners, gums, sugars, and other additives. This can be challenging to provide a consistent blend quality in the most efficient manner possible.

To meet this challenge ZM Technologies offers two types of shear blenders based upon the popular LF platform. This allows for shared wear items for your pumps and easy piping solutions. The wide range of mechanical seal materials (single and double mechanical) and elastomers from the LF line are also available to fine tune the shear blender to the customer’s needs.

The SBH/SBI shear blender offers flexibility for a variety of solutions. The clearance of the SB shear blender can be adjusted from a 0.3 to 1.2 mm (0.01″ to 0.05″). Therefore, only the minimal necessary shear is applied to the product. This reduces damage, prevents overheating, and lowers power consumption. This Shear Blender is perfect for inline mixing of premixed products and can also be used to minimize undissolved particles or to achieve the specified final mix.

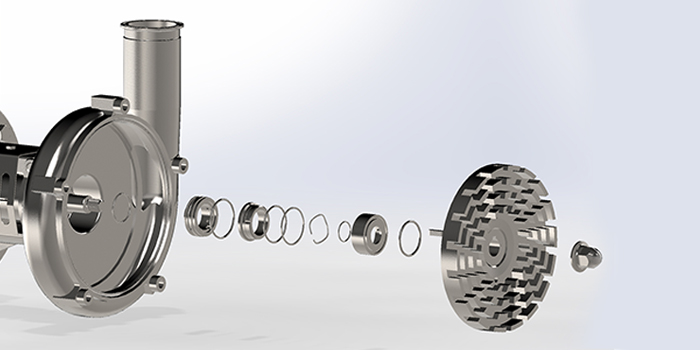

SBH SHEAR BLENDER

The High Shear Mixer

Advantages:

- Uniform product batches.

- Better mixing means less raw material

- Time saving process.

- Less ClP time in the system due to improved solution quality.

- Easy adjustable design for different applications with same pump.

- Same wear parts as standard centrifugal pumps.

- Different sizes to meet the application.

SBH SHEAR BLENDER PRODUCT SPECS

When highest possible product shear is required, the SBH shear blender offers tightened clearances and the media goes through several shearing stages. This improves the solution quality, for example, by reducing the size of crystals for quicker solubility. The Shear Blender SBH ensures smoother product consistency and texture, uniform blending and repeatable mixing results in all processes.

SBH FEATURES

- Medium – High Shear Levels

- 316L Stainless Steel Heavy Wall Construction

- Cast and Machined

- 304 Stainless Steel Adapter

- Dynamically Balanced Impeller

- 316L Stainless Steel Shaft

SBH PERFORMANCE OVERVIEW

Models: 6

Max Flow Rate: 200 GPM / 45 Mᵌ/hr

Seal Specifications: 2 Seal Options

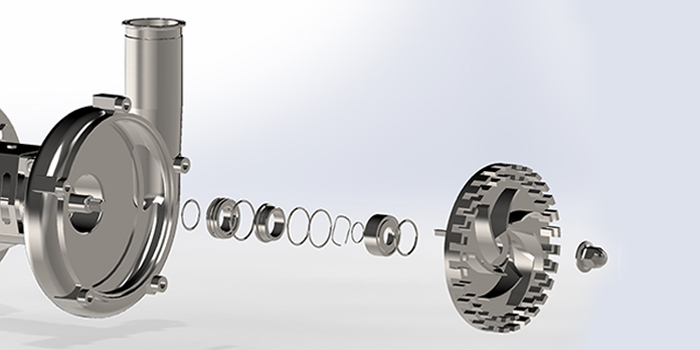

SBI SHEAR PUMP

The High Shear Mixer Pump

Advantages:

- Uniform product batches.

- Better mixing means less raw material

- Time saving process.

- Less ClP time in the system due to improved solution quality.

- Easy adjustable design for different applications with same pump.

- Same wear parts as standard centrifugal pumps.

- Different sizes to meet the application.

SBI SHEAR BLENDER PRODUCT SPECS

The SBI Pump Series pumps and blends product in a single stage. This innovative design can move product and create considerable pressure by way of a hybrid impeller.

This fine-tuned impeller design – used in combination with two rows of rectangular shear teeth – can attain amazing performance levels. As with the SBH, the SBI is based on the Ampco LF Series pump and offers multiple front loading seal options.

SBI FEATURES

- Low – Medium Shear Levels.

- Combination Integrated Impeller and Dynamic Shear Teeth.

- Pump and Blend in a Single Stage.

- Cast and Machined.

- 304 Stainless Steel Adapter.

- Dynamically Balanced Impeller.

- 316L Stainless Steel Shaft.

SBI PERFORMANCE OVERVIEW

Models: 7

Max Flow Rate: 510 GPM / 116 Mᵌ/hr

Max Powder Induction Rate: 150 lbs/min / 68 kg/min

Seal Specifications: 2 Seal Options

POWDER INDUCTION PRODUCTS

| Application Specification | SHEAR-Blend | POWDER-Max | DRY-Blend | SIMPLE-Blend |

|---|---|---|---|---|

| Ideal Operating Flow Rates (low viscosity) | 50-510 gpm (11-116 m3/hr) | 30-210 gpm (7-48 m3/hr) | 40-150 gpm (9-34 m3/hr) | 30-210 gpm (7-48 m3/hr) |

| Powder Feed Rates (highly soluable) | Up to 150 lb./min. (68 kg/min.) | Up to 300 lb./min. (136kg/min.) | Up to 350 lb./min. (159 kg/min.) | Up to 300 lb./min. (136kg/min.) |

| Maximum Viscosity | 1,000 cPs | 2,500 cPs | 2,500 cPs | 2,500 cPs |

| Dynamic Shearing Teeth | Yes | Yes | No | No |