Sanitary Valves

Rieger Valves

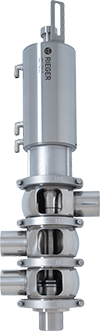

ZM Technologies is a proud distributor of Rieger Valves. Our valves are precision engineered to meet the exacting demands of the food, pharmaceutical, chemical, and biotechnological industries, or wherever productivity, safety and quality are required. Committed to the customer by providing innovative solutions that meet or exceed industry standards, Rieger offers a full-line of aseptic and hygienic valves, including BioCheck Sampling, Incline Seat, Divert, Double Seal, Overflow and Mix Proof valves.

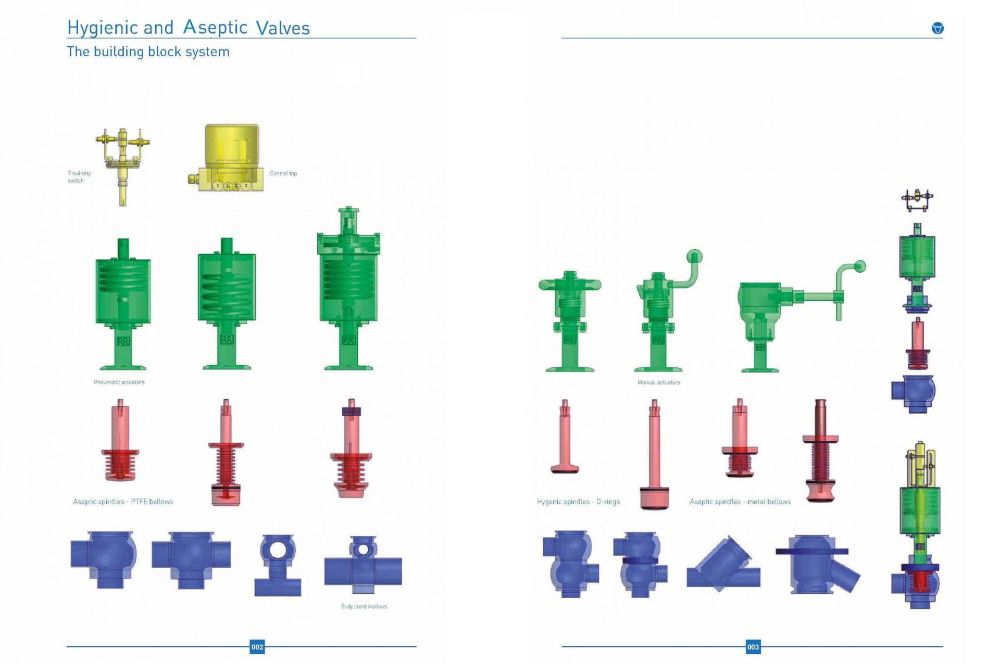

Rieger Building Bock System

ASEPTIC/Hygienic VALVES

ZM Technologies partners with Rieger Aseptic Valves feature PTFE bellows to hermetically seal the product space with the environment. Superior to common metal bellow design, our low-adhesive PTFE bellows provide one-piece sealing that’s resistant to almost any medium. Installation flexibility and unrivaled cleanability of the open folds make Rieger aseptic valves the number one choice for dairy and pharmaceutical applications.

Mix Proof VALVES

ZM Technologies is a proud distributor of Rieger Mix Proof Valves designed to ensure reliable protection for your products. Proven in the leading processing plants of the beverage, dairy, food, and pharmaceutical industries, Available as Single Seat, Divert, Tank Outlet, Mix Proof, Overflow and Safety Valves, Rieger Hygienic Valves feature our unique Building Block System. Should process conditions change, our valves are designed to change with them — from hygienic to aseptic applications.

The RIEGER ADvantages

- Valve body from solid billet - many mounting positions possible depending on draining.

- Optimum cleanability.

- Interior surface Ra ≤ 0,8 µm (32 rms standard).

- Optional interior surfaces available upon request.

- No sump or dome in product space.

- No dead space.

- Valves available meeting 3-A standards and EHEDG guidelines.

- Gentle product handling,

- Easy maintenance without special tools.

- Minimal downtime due to block design.

- tube outlets available as DIN, OD tube and ISO.

- Seals conform with FDA, 3-A.

- Thanks to the building block system change to aseptic type is simple.

- Long stroke and full stroke valves are available.

The pneumatic actuator can be ordered as

- Air-to-open/spring-to-close, spring-to-open/air-to-close or air-to-oprn/air-to-close.

- A 3-position actuator permits simple static dosing processes.

- Proximity switches and control tops optional.

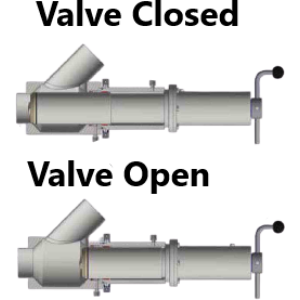

Full Stroke (Rail Car) VALVES

Rieger‘s aseptic and hygienic Full Stroke Valves are best-in-class valves for high viscosity products, such as tomato paste, jam or smoothies. With the full cylindric stem, the valves open to 100% of the tube size, which avoids any dead spaces within the valve and reduces pressure drops to a minimum. An optional steam barrier guarantees hermetic sealing against the environment.

Industries of application: tomato processing, food, dairy and cosmetics.

DESIGN FEATURES

- Valve body made from solid bar.

- No dead spaces.

- Resistant to aggressive fluids.

- Hermetically sealed against the environment through a steam-barrier.

- Drainable.

- Change seals without special tools.

MAINTENANCE BENEFITS

- Maximize life cycles.

- Ease of cleaning – CIP/SIP.

- Modular system makes changing actuator.

- More convenient – from pneumatic to manual or vice versa..

- Long service life of PEEK sealing.

OPTIONS INCLUDE

- Wide variety of installation positions available.

- High quality product surface finishes available, including electropolishing.

- Electronic feedback

ACTUATOR VERSIONS

- Automatic actuator

- Manual activation