INDUSTRIAL PUMP & MIXER SEALS

THINK OUTSIDE THE BOX.

Do mechanical seals belong in a pump stuffing box made for packing?

Do mechanical seals provide the best longevity inside an area meant for packing?

STANDARD PUMP STUFFING BOXES HAVE LITTLE ROOM FOR SEALS – AS A RESULT A SEAL RUNS HOT. REMEMBER . . . . . . . HEAT KILLS.

THE ZN SINGLE SEAL

We have all seen plenty of mechanical seals introduced to the market over the last few years. ZM Technologies has introduced a truly new mechanical seal for centrifugal pumps. This is a new concept in cartridge mechanical seals. This cartridge seal is not a modification or a duplicate of any seal on the market.

The ZN Seal has a unique approach to seal installation, design, and repair:

- This seal bolts OUTSIDE the stuffing box which allows for better cooling, better lubrication, and superior performance than the competition.

- Different Repair Kits are available to suit every purpose.

THE ZA SINGLE SEAL

ZM Technologies has introduced a truly new mechanical seal for Goulds and Durco® pumps. This is a new concept in cartridge mechanical seals. This patented cartridge seal is not a modification or a duplicate of any seal on the market.

The ZA Seal has a unique approach to seal installation, design, and repair.

- Designed from a clean slate, the ZA seal is a No Stuffing Box Seal. This allows for better cooling, better lubrication, and superior performance than the competition.

- The tapered gland design allows the seal to operate for an extended time without the need for a flush of any kind.

- The ZA seal installs into a ZMT engineered pump back-plate. Eliminating the pump stuffing box entirely.

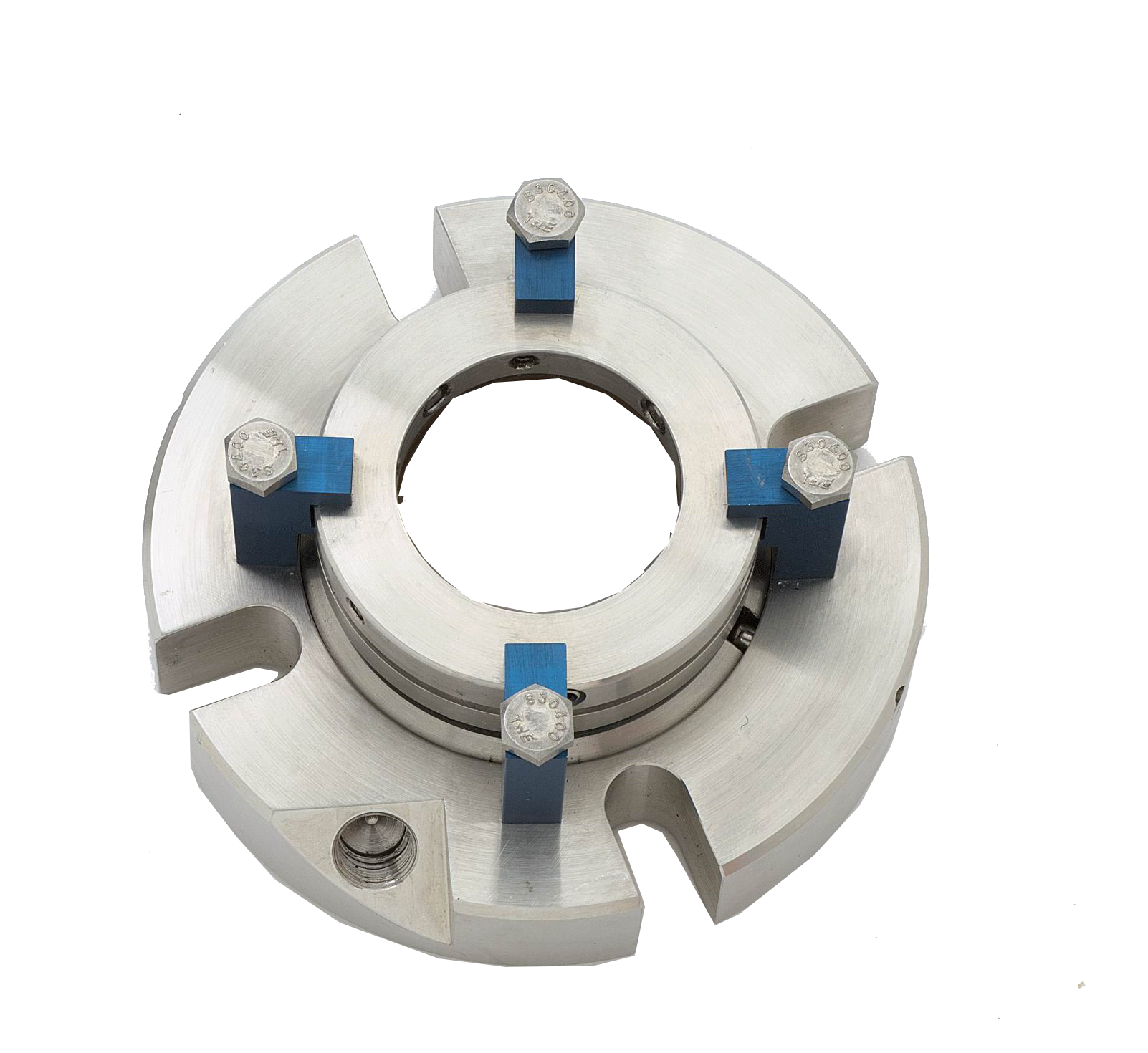

THE ZND DOUBLE SEAL

ZM Technologies has introduced a truly new cartridge double seal for centrifugal pumps. The double/tandem design is built for mild to extreme applications. The ZND Seal has a unique approach to seal installation, design, and repair. Different Repair Kits are available to suit every purpose.

There are many unique feaures: the double cartridge seal uses a standard bi-directional pumping ring, which allows for half the water consumption of other double seals; an inner cartridge design allows for ease of repair and a quick change to different seal materials; the outer seal is designed to operate under full product pressure.

The unique features are as follows:

- Seal is installed through the front of the back plate. Unlike all other seals that bolt to the back of the stuffing box, our seal eliminates the stuffing box entirely.

- The benefits of the stuffing box redesign is a simpler installation (no longer need to remove the stuffing box to install the seal), and more clearances for better lubrication and cooling.

- The seal design is simple in concept and simple to manufacture. The result is that the seal is inexpensive and repair cost is minimal as well.

- The simple design allows for easy repair in the field, requiring little time and minimum experience to repair a ZMT seal.