My account

Search

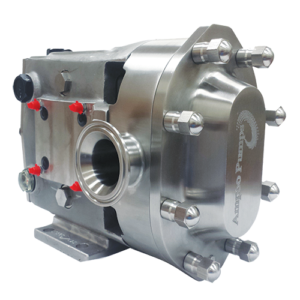

ZP2 SERIES PUMPS

THE ZP2 SERIES PUMPS HAVE BEEN DESIGNED TO BE CIP-ABLE AND OPERATE AT HIGHER PRESSURES.

- Uses larger shaft diameters.

- Sanitary rotor nuts and with the use of rotor O-rings,

- ZP2 is CIP-able without requiring disassembly.

- ZP2 is capable of withstanding pressures of up to 450 PSI.

- 3A Certified.

EVERY ZP2 PUMP INCLUDES THE FOLLOWING FEATURES AS STANDARD:

- 304 SS gearcase.

- Stainless steel splash plate reducing damage to bearings from water intrusion during the wash-down process (this is a major cause of bearing failure).

- Stainless Steel bearing retainers.

- 17-4 PH shafts.

- Helical cut gears.

- 4-way mounting.

- Threaded grease zerks,

- Anti-microbial lube and gasketed stainless steel clean-out plugs at no-charge.

The ZP2, like the ZP1, is 100% part-for-part, hydraulically, and dimensionally interchangeable with the competition’s Universal 2.

Contact ZM Technologies application engineering team to find the right ZP Series pump for your application.EVERY ZP2 PUMP INCLUDES THE FOLLOWING FEATURES AS STANDARD:

- Front-loading seals are located closer to the product flow, offering improved CIP-ability with no disassembly required.

- Front-loading seals allow for ease of maintenance and reduced service time.

- As opposed to our competitors’ similar pumps, this seal is a better balanced design which generates less heat and promotes longer seal life.

- Cover design maximizes exposure of the cover o-ring to the CIP fluid.

- Free drain design improves CIP-ability while maintaining maximum pump efficiency.

- CIP holes in rotor ensure turbulent flow to the cover hub.

- Elimination of dead zones in body bore improves cleanability and increases seal life.

- The ZP3 pump is mounted on a ZP2 gear case, including shafts, to maximize parts interchangeability.

- Existing ZP2 pumps (and our competitors’ similar pumps) can be upgraded to the ZP3 design with new rotors, new seals and re-machining the existing rotor case.

- New pumps can be reconditioned 2 to 3 times.

REMANUFACTURING PROGRAM

ZM Technologies offers remanufacturing services for ZPl, ZP2, ZP3 Series pumps and competing models Universal 1 & 2. The pumps are rebuilt with oversized rotors to extend the useful life of the pump. A remanufactured pump includes new shafts, gears, bearings, rotors and a full one-year factory warranty. Pumps can be remanufactured in two weeks and are 30% less than the cost of a new pump.

Available Models | |||

|---|---|---|---|

| Pump Model Number | Curves | Data Sheet | |

| ZP2-6 | Curves | Dimensions | |

| ZP2-15 | Curves | Dimensions | |

| ZP2-18 | Curves | Dimensions | |

| ZP2-30 | Curves | Dimensions | |

| ZP2-40 | Curves | Dimensions | |

| ZP2-45 | Curves | Dimensions | |

| ZP2-60 | Curves | Dimensions | |

| ZP2-130 | Curves | Dimensions | |

| ZP2-180 | Curves | Dimensions | |

| ZP2-210 | Curves | Dimensions | |

| ZP2-220 | Curves | Dimensions | |

| ZP2-320 | Curves | Dimensions | |

Available Rectangle Flange Models | |||

|---|---|---|---|

| Pump Model Number | Curves | Data Sheet | |

| ZP2-034 | Curves | Dimensions | |

| ZP2-064 | Curves | Dimensions | |

| ZP2-134 | Curves | Dimensions | |

| ZP2-184 | Curves | Dimensions | |

| ZP2-214 | Curves | Dimensions | |

| ZP2-224 | Curves | Dimensions | |