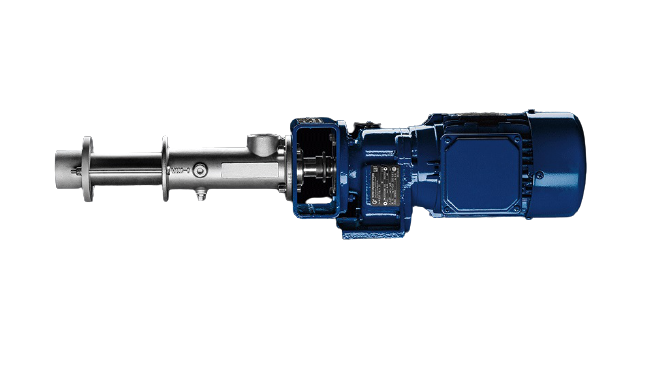

D SERIES METERING PROGRESSIVE CAVITY PUMP

THIS PROGRESSIVE CAVITY METERING PUMP OFFERS:

- A modular system for quick and easy conversion.

- Low pulsation pumping for accurate metering.

- High metering accuracy (deviation ±1%).

- Easy maintenance due to the plug-in connection.

- Material combinations available for all conveying products.

- Multiple drive combinations available.

D SERIES PERFORMANCE OVERVIEW

Models: 8 Available

Max Outlet Pressure: 700 PSI / 48 BAR

Max Flow Rate: 528 GPM / 2,000 L/hr

Max Viscosity: 1,200 cP

Seal Specifications: Various Sealing Options

PUMP SIZE RANGES

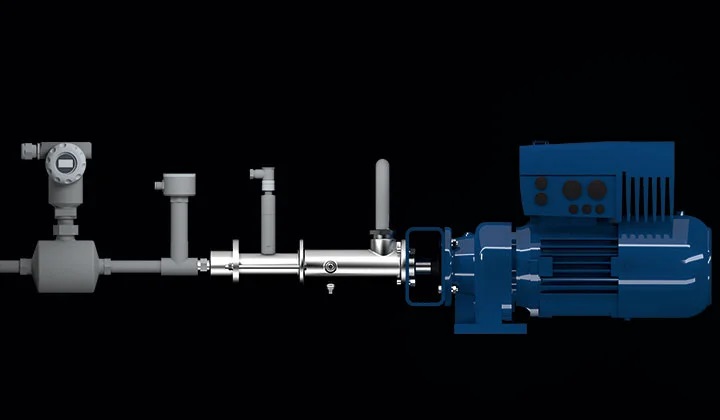

THE SMART DOSING PUMP

FOR THIN TO HIGHLY VISCOUS MEDIA & SOLIDS AND CORROSIVE LIQUIDS

The Smart Dosing Pump (SDP) with integrated control system is the intelligent dosing pump for a wide variety of applications. It combines the classic dosing benefits of a progressive cavity pump with modern, decentralized control concepts. The concept of a compact process module with a control system directly integrated into the pump is very unique. This has impressed experts from the process industry. Because of this, SDP received the Innovation Award from ACHEMA during the chemical industry event in 2018. This module consists of a drive, the associated SEEPEX control software as well as flow rate sensors and optional safety functions.

- Conveying capacity: 0.079 GPH – 528.34 GPH (0.3 l/h – 2,000 l/h).

- Pressure: up to 725 PSI (48 bar).

- Integrated PLC to enable stand alone operation in distributed control systems.

BENEFITS

- Easy implementation of complex dosing in continuous and batch mode.

- Realization of short filling times and resource-efficient media pumping.

- Cost reduction due to minimal pulsation and high repeatability.

- Easy integration into higher-level controls and automation systems.

- Operation via handheld panel or various fieldbus systems.

- Broad pumping performance range through our modular system.

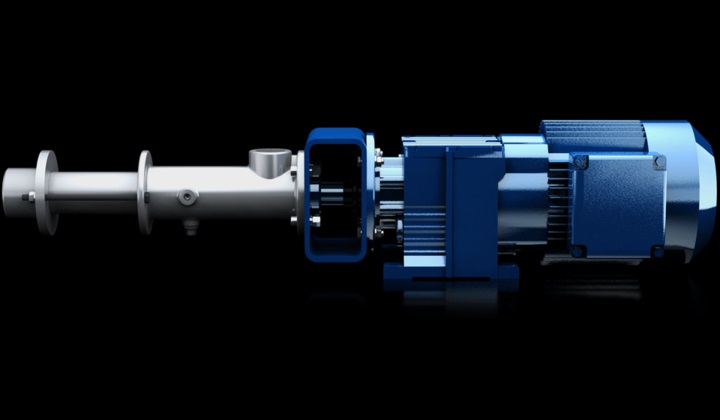

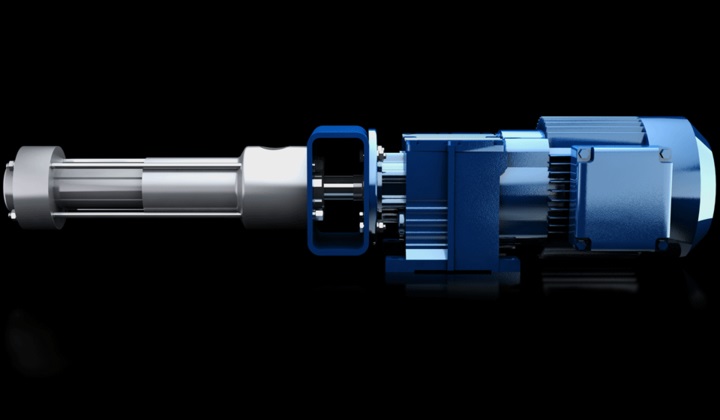

THE INTELLIGENT METERING PUMP

SUITABLE FOR LOW TO VISCOUS FLOWABLE MEDIA & SHEAR-SENSITIVE AND CHEMICALLY AGGRESSIVE LIQUIDS

The Intelligent Metering Pump (IMP) design incorporates a gear reducer and a programmable vector drive in a compact design for precise metering. Metering parameters can be pre-configured on an Electronic Programming Module (EPM) memory chip, making conversion from a previous drive to a new drive or a change in parameters as easy as inserting the EPM chip.

- Suitable for low to viscous flowable media, as well as shear-sensitive and chemically aggressive media.

- Conveying capacity: 1.05 GPH – 250 GPH (4 l/h – 945 l/h).

- Pressure: up to 350 PSI (24 bar).

- Incorporates Variable Frequency Drive (VFD) with Electronic Programming Module (EPM) memory chip.

- Short, compact design with directly flange-mounted drive (block type).

BENEFITS

- Reduced costs due to inexpensive rotating unit.

- Low slip (internal back flow) provides performance efficiency and less wear on components.

- No check valves, vapor locking, or blockage by solids.

- Valveless flow control for ease of operation.

- Simple and predictive maintenance due to minimal components.

- High corrosion resistance due to the variety of components made of Hastelloy C or Titanium.

- Accessories can easily be connected to the drive via control terminals.

- Downtime is eliminated with Electronic Programming Module (EPM) memory chips when switching drives or changing parameters.

TECHNICAL DATA

- Modular components for quick and easy conversion to larger or smaller sizes.

- Low pulsation pumping without pulsation dampeners or compensators.

- High metering accuracy (deviation +/- 1%).

- Low shear pumping.

- Constant flow, independent of pressure.

- Conducive for horizontal or vertical mounting.

- Range of materials of construction available, suitable for all types of conveyed media.

- Multiple drive combinations possible.

- Controller keypad allows for manual speed control, display of pump speed / RPM or flow, fault indication, and the ability to change factory settings.

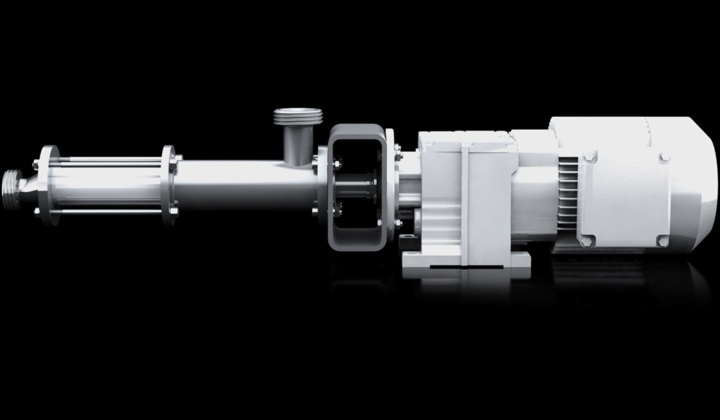

MD RANGE

FOR LOW TO HIGHLY VISCOUS MEDIA & SHEAR-SENSITIVE AND CHEMICALLY AGGRESSIVE LIQUIDS

SEEPEX MD range pumps are compact units with a high metering accuracy. The stainless steel or synthetic material casings are highly compatible with chemically corrosive media.

- Conveying capacity: 0.016 GPH – 264 GPH (0.06 l/h – 1,000 l/h).

- Pressure: up to 350 PSI (24 bar).

- Short, compact design with directly flange-mounted drive (block type).

- Casing of stainless steel or synthetic material.

- High metering accuracy.

- High corrosion resistance due to the variety of components made of Hastelloy C or titanium.

- Low maintenance costs.

MDP RANGE

FOR LOW TO HIGHLY VISCOUS MEDIA & SHEAR-SENSITIVE AND CHEMICALLY AGGRESSIVE LIQUIDS

SEEPEX MDP range pumps are available with stainless steel or synthetic casing. Along with stators made of PTFE, these pumps handle and meter hydrocarbon-containing media such as paints, varnishes, solvents, plasticizers and others.

- Conveying capacity: 0.264 GPH – 132 GPH (1 l/h – 500 l/h).

- Pressure: up to 180 PSI (12 bar).

- Single-part, jointless and wear-resistant rotating unit made of synthetic material.

BENEFITS

- Reduced costs due to inexpensive rotating unit.

- Easy maintenance.

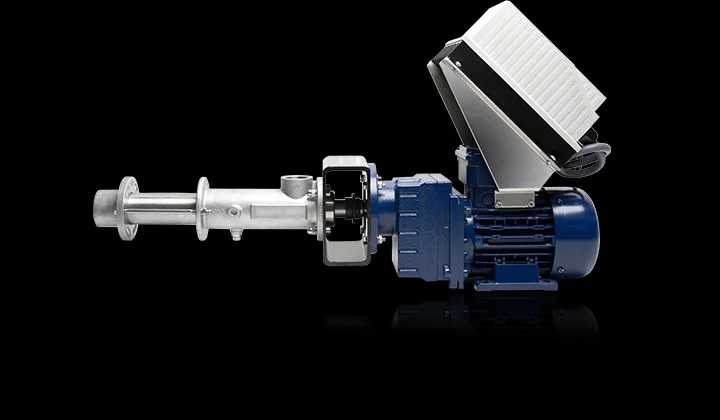

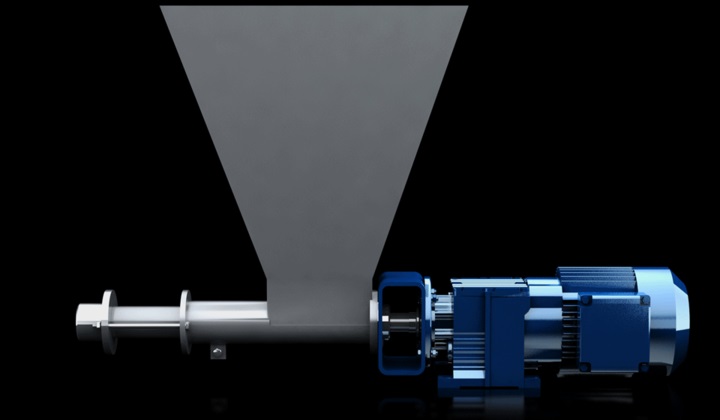

MDT RANGE

FOR HIGHLY VISCOUS PRODUCTS WITH LOW FLOWABILITY

SEEPEX MDT range pumps have an open hopper with cylindrical compression zone. The auger feed screw on the coupling rod feeds the viscous product to the rotor and stator.

- Conveying capacity: 1.32 GPH – 132 GPH (5 l/h – 500 l/h).

- Pressure: up to 350 PSI (24 bar).

- Open hopper pump with compression zone and auger feed screw.

BENEFITS

- High volumetric efficiency with optimum filling of the conveying chamber due to the system pressure produced in the compression zone.

MDC RANGE

FOR NON-VISCOUS TO VISCOUS MEDIA

SEEPEX MDC range pumps are equipped with open aseptic fork joints. The pumps meet the highest hygienic requirements as well as providing corrosion and wear resistance.

- Conveying capacity: 0.132 GPH – 132 GPH (0.5 l/h – 500 l/h).

- Pressure: up to 350 PSI (24 bar).

- Highest hygienic standards as well as corrosion and wear resistance.

- 3-A Sanitary Standards and FDA approved.

BENEFITS

- Particularly easy to maintain (open joint consisting of only a few components).

- Guaranteed residue-free: open aseptic fork joint with CIP cleaning.

MDF RANGE

FOR NON-VISCOUS TO VISCOUS MEDIA

SEEPEX MDF range pumps are used for draining barrels.

- Conveying capacity: 0.132 GPH – 264 GPH (0.5 l/h – 1,000 l/h).

- Pressure: up to 175 PSI (12 bar).

- Draining pump for open top barrels or closed barrels with 2″ bung holes.

BENEFITS

- Low weight, easy to transport with the handle.

- Problem-free barrel emptying due to the suction side inlet pressure.

- Easy and convenient to use.